Average Inventory Turns

In the world of business and inventory management, understanding key metrics is essential for making informed decisions. One such metric that holds significant value for businesses, especially in the retail and manufacturing sectors, is the Average Inventory Turns or Inventory Turnover Ratio. This ratio provides valuable insights into a company's inventory management efficiency and overall financial health.

In this comprehensive article, we will delve deep into the concept of Average Inventory Turns, exploring its definition, calculation, and practical implications. By the end of this guide, you will have a solid understanding of how this metric works and why it matters for your business.

Understanding Average Inventory Turns

Average Inventory Turns, often simply referred to as inventory turns, is a critical financial metric that measures how effectively a company manages its inventory. It quantifies the number of times a business sells and replaces its entire inventory in a given period, typically over a year. In simpler terms, it reflects how quickly a company’s inventory moves from storage to sales.

The concept of inventory turns is particularly important because it directly impacts a company's cash flow, profitability, and overall operational efficiency. By tracking this metric, businesses can identify areas for improvement, optimize their inventory management strategies, and ensure they are meeting customer demands effectively.

Why Inventory Turns Matter

Inventory turns serve as a vital performance indicator for any business, especially those with significant inventory investments. Here are some key reasons why understanding and optimizing inventory turns is essential:

- Cash Flow Management: High inventory turns indicate that a company is efficiently managing its inventory, reducing the risk of excess stock and tying up cash in unused assets. This frees up cash for other business operations and investments.

- Profitability: Efficient inventory management leads to improved profitability. By minimizing the time inventory sits idle, businesses can maximize sales and minimize carrying costs associated with storing excess inventory.

- Customer Satisfaction: Optimal inventory turns ensure that businesses have the right products available when customers need them. This helps prevent stockouts and enhances customer satisfaction, leading to increased sales and loyalty.

- Competitive Advantage: Businesses with higher inventory turns often have a competitive edge. They can respond quickly to market demands, adapt to changing trends, and maintain a lean and efficient supply chain.

Calculating Average Inventory Turns

Calculating the Average Inventory Turns ratio is relatively straightforward, but it requires accurate data and a clear understanding of the business’s inventory and sales processes.

Formula for Inventory Turns

The basic formula for calculating Average Inventory Turns is as follows:

Average Inventory Turns = Cost of Goods Sold (COGS) / Average Inventory Value

Here's a breakdown of the key components:

- Cost of Goods Sold (COGS): This represents the direct cost of producing or purchasing the goods sold by the business. It includes the cost of raw materials, labor, and other direct expenses related to manufacturing or acquiring inventory.

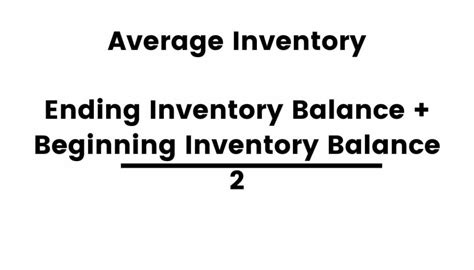

- Average Inventory Value: This is the average value of the business's inventory over a specific period. It is calculated by adding the beginning inventory value and the ending inventory value for that period and dividing the result by two. The beginning inventory value is the value of inventory at the start of the period, while the ending inventory value is the value at the end of the period.

Example Calculation

Let’s illustrate the calculation with a practical example. Imagine a retail store named “EcoGoods” that specializes in sustainable home products.

For the year 2023, EcoGoods has the following data:

- Cost of Goods Sold (COGS): $500,000

- Beginning Inventory Value: $100,000

- Ending Inventory Value: $80,000

To calculate the Average Inventory Turns for EcoGoods in 2023:

Average Inventory Turns = $500,000 / (( $100,000 + $80,000 ) / 2)

Average Inventory Turns = $500,000 / $90,000

Average Inventory Turns ≈ 5.56

So, EcoGoods turned its inventory over approximately 5.56 times in the year 2023.

Interpreting Inventory Turns

Understanding the calculated inventory turns is crucial for drawing meaningful insights. Here are some key considerations when interpreting this metric:

Industry Benchmarks

Inventory turns can vary significantly across different industries. It’s essential to compare your business’s inventory turns with industry benchmarks to assess your performance relative to competitors.

For instance, a fashion retailer might aim for higher inventory turns to keep up with fast-changing trends, while a wholesale distributor might have lower turns due to bulk purchases and longer holding periods.

Ideal Inventory Turns

The “ideal” inventory turns vary depending on the nature of the business and its industry. Generally, higher inventory turns are desirable as they indicate efficient inventory management and reduced carrying costs.

However, it's crucial to strike a balance. Extremely high inventory turns might suggest that the business is under-investing in inventory, leading to stockouts and lost sales opportunities. Finding the right balance is key to optimizing inventory management.

Seasonal Variations

Businesses often experience seasonal variations in their inventory turns. For example, a retail store might have higher turns during the holiday season and lower turns during off-peak periods. It’s essential to consider these seasonal patterns when analyzing inventory turns over time.

Strategies for Optimizing Inventory Turns

Now that we understand the importance and calculation of Average Inventory Turns, let’s explore some practical strategies businesses can employ to optimize their inventory management and improve turns.

1. Implement Just-in-Time (JIT) Inventory Management

JIT inventory management is a strategy that aims to minimize inventory levels by synchronizing production and supply with demand. By reducing excess inventory, businesses can lower carrying costs and improve overall inventory turns.

To implement JIT, businesses should:

- Accurately forecast demand to ensure sufficient stock without excess.

- Establish strong relationships with suppliers to ensure timely deliveries.

- Invest in efficient inventory tracking systems to monitor stock levels in real-time.

2. Optimize Reorder Points

Reorder points are the inventory levels at which a business should place new orders to replenish stock. Optimizing reorder points is crucial for maintaining a steady flow of inventory without overstocking.

Businesses should consider factors like lead times, demand variability, and safety stock levels when setting reorder points. Regularly reviewing and adjusting these points can help prevent stockouts and excess inventory.

3. Embrace Technology for Better Inventory Management

Technology plays a vital role in modern inventory management. Businesses can leverage advanced software and systems to automate inventory tracking, optimize reorder processes, and gain real-time insights into stock levels.

Some key technologies to consider include:

- Inventory Management Software: These tools help track inventory levels, monitor sales data, and provide insights for better decision-making.

- Barcode Scanning: Implementing barcode systems allows for quick and accurate inventory counting and tracking.

- RFID Technology: Radio-Frequency Identification (RFID) offers real-time visibility into inventory, enabling efficient tracking and management.

4. Collaborate with Suppliers for Better Planning

Effective collaboration with suppliers can lead to improved inventory management. By sharing demand forecasts and working closely with suppliers, businesses can ensure a steady supply of inventory without excess stock.

Consider the following strategies:

- Establish long-term relationships with reliable suppliers who can adapt to your business's needs.

- Negotiate flexible ordering options, such as drop shipping or custom production runs.

- Explore consignment arrangements where suppliers hold inventory until it's sold, reducing your carrying costs.

5. Regularly Review and Analyze Inventory Data

Regularly reviewing and analyzing inventory data is crucial for identifying areas of improvement. By tracking key metrics like inventory turns, businesses can make informed decisions to optimize their inventory management strategies.

Consider the following practices:

- Conduct periodic inventory audits to identify discrepancies and ensure accurate data.

- Analyze sales data to identify fast-moving and slow-moving inventory items. Focus on optimizing the management of slow-moving items to improve overall turns.

- Utilize inventory analytics tools to gain insights into stock levels, sales trends, and customer behavior.

The Impact of Average Inventory Turns on Business Success

Optimizing Average Inventory Turns has a direct and positive impact on a business’s overall success and financial health. Here’s a deeper look at how improved inventory turns can benefit your business:

1. Enhanced Cash Flow and Working Capital

By increasing inventory turns, businesses can reduce the amount of capital tied up in inventory. This frees up cash, which can be reinvested into other areas of the business, such as marketing, research and development, or debt repayment. Improved cash flow also provides a buffer against unexpected expenses and allows for better financial flexibility.

2. Improved Profitability and Margins

Efficient inventory management leads to increased profitability. When inventory turns are optimized, businesses can minimize carrying costs, such as storage, insurance, and obsolescence risks. Additionally, by reducing excess inventory, businesses can negotiate better pricing with suppliers, further boosting margins.

3. Enhanced Competitive Advantage

Businesses with higher inventory turns often have a competitive edge. They can respond quickly to market demands, adapt to changing trends, and maintain a lean and efficient supply chain. This agility allows them to stay ahead of competitors and meet customer expectations more effectively.

4. Reduced Risk of Obsolescence and Stockouts

Optimal inventory turns help businesses strike a balance between having sufficient stock to meet demand and avoiding excess inventory. By managing inventory levels effectively, businesses can minimize the risk of stockouts, ensuring they have the right products available when customers need them. Additionally, reducing excess inventory lowers the risk of obsolescence, as outdated or unsold items are less likely to accumulate.

5. Improved Customer Satisfaction and Loyalty

By maintaining optimal inventory levels, businesses can ensure that customers have access to the products they want when they need them. This reduces the likelihood of disappointed customers and increases the chances of repeat purchases and referrals. Improved customer satisfaction and loyalty are key factors in long-term business success and growth.

Conclusion

Average Inventory Turns is a powerful metric that provides invaluable insights into a business’s inventory management efficiency and financial health. By understanding and optimizing this metric, businesses can enhance their cash flow, profitability, and overall competitiveness. Through strategies like JIT inventory management, optimizing reorder points, embracing technology, and collaborating with suppliers, businesses can achieve higher inventory turns and unlock numerous benefits.

Remember, inventory management is an ongoing process, and regular analysis and adjustment are key to staying ahead in a dynamic business landscape. By staying focused on optimizing Average Inventory Turns, businesses can ensure they are well-positioned for long-term success and growth.

How frequently should businesses review their Average Inventory Turns?

+Businesses should review their Average Inventory Turns on a regular basis, ideally on a monthly or quarterly basis. This allows for timely adjustments and ensures that inventory management strategies remain aligned with business goals and market dynamics.

Can businesses have different inventory turns for different product categories?

+Yes, it is common for businesses to have varying inventory turns across different product categories. This is because each category may have unique demand patterns, lead times, and customer preferences. By analyzing inventory turns at a granular level, businesses can optimize inventory management for each category individually.

What are some common challenges businesses face when trying to improve inventory turns?

+Some common challenges include inaccurate demand forecasting, long lead times from suppliers, and difficulty in balancing customer service levels with inventory levels. Overcoming these challenges often requires a combination of strategic planning, technological solutions, and strong supplier relationships.