Production Cost Per Unit Formula

In the world of manufacturing and business, understanding the production cost per unit is crucial for making informed decisions and optimizing operations. This metric provides insights into the financial health and efficiency of a production process, helping businesses identify areas for improvement and maintain profitability. In this comprehensive guide, we delve into the intricacies of the production cost per unit formula, exploring its components, applications, and real-world examples.

Understanding the Production Cost Per Unit Formula

The production cost per unit formula is a fundamental tool for calculating the average cost associated with producing a single unit of a product. It considers various expenses incurred during the manufacturing process, offering a comprehensive view of the costs involved. By analyzing this formula, businesses can make strategic choices, set competitive prices, and enhance their overall financial performance.

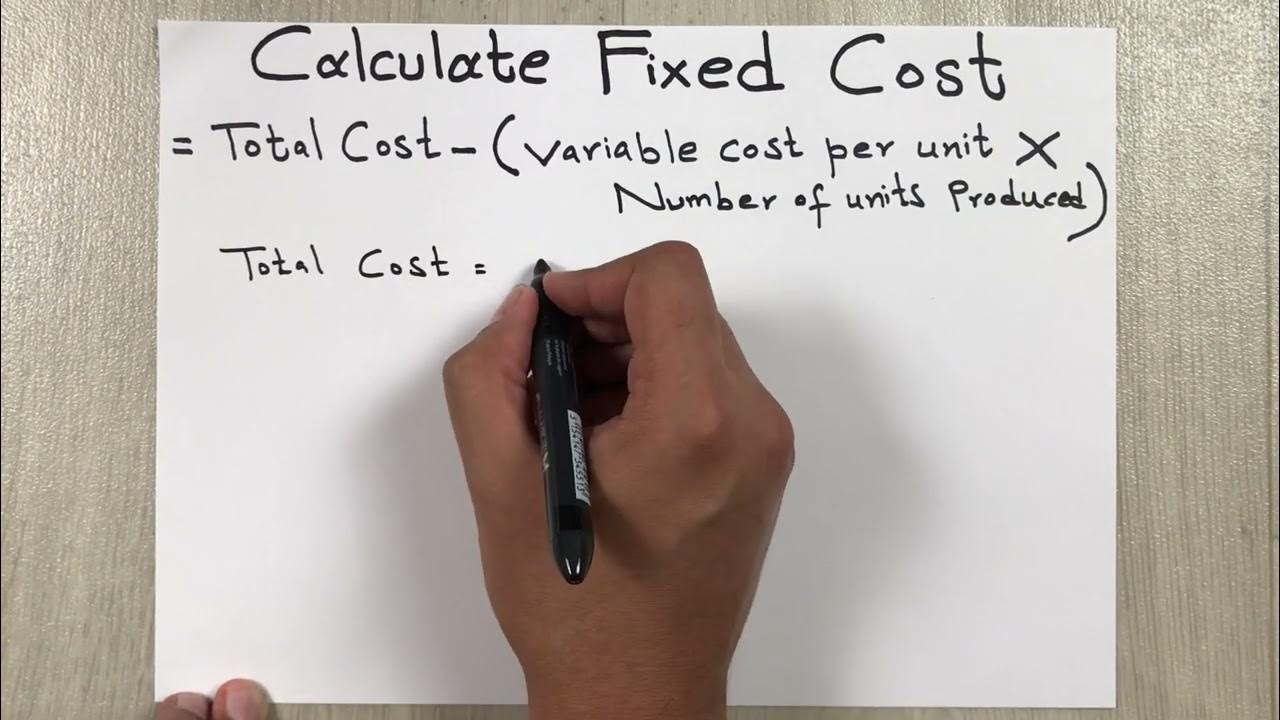

The formula for calculating the production cost per unit is as follows:

Production Cost Per Unit = (Total Production Costs) / (Number of Units Produced)

Let's break down the components of this formula and explore how each element contributes to the overall calculation.

Total Production Costs

Total production costs encompass all the expenses directly related to the manufacturing process. These costs can be categorized into several key components:

- Raw Materials: The cost of the raw materials or components required to produce the product. This includes the purchase price, shipping expenses, and any associated taxes.

- Labor: The wages and benefits paid to the workforce involved in the production process. This includes both direct labor costs, such as manufacturing employees, and indirect labor costs, like maintenance and quality control staff.

- Overhead: Overhead costs are the indirect expenses associated with running the manufacturing facility. These may include rent, utilities, insurance, depreciation of equipment, and administrative expenses.

- Manufacturing Supplies: The cost of consumable items used in the production process, such as lubricants, cleaning chemicals, and packaging materials.

- Other Direct Costs: Any additional expenses directly attributable to the production process, such as testing or quality assurance costs.

It's essential to accurately track and allocate these costs to ensure a precise calculation of the total production costs.

Number of Units Produced

The number of units produced represents the quantity of items manufactured during a specific period. This value is crucial for calculating the average cost per unit. It is typically determined by the production output of the facility over a defined timeframe, such as a month or a quarter.

Calculating Production Cost Per Unit

To calculate the production cost per unit, follow these steps:

- Determine the total production costs for the relevant period.

- Divide the total production costs by the number of units produced during that period.

- The resulting value represents the average cost incurred to produce each unit of the product.

For example, let's consider a manufacturing company that produces electronic gadgets. The total production costs for a quarter amount to $500,000, and the company produced 10,000 units during that period. Using the formula, the production cost per unit would be:

Production Cost Per Unit = $500,000 / 10,000 = $50

Therefore, the average cost to produce each electronic gadget is $50.

Applications and Benefits of the Production Cost Per Unit Formula

The production cost per unit formula serves as a powerful tool for businesses, offering several critical applications and benefits:

Pricing Strategy

Understanding the production cost per unit is essential for setting competitive and profitable prices. By knowing the average cost, businesses can determine the minimum price at which they can sell their products while maintaining profitability. This information is crucial for pricing strategies, especially in highly competitive markets.

Cost Control and Optimization

The formula provides insights into the efficiency of the production process. By analyzing the components of total production costs, businesses can identify areas where costs can be reduced or optimized. For example, negotiating better raw material prices, improving labor productivity, or streamlining overhead expenses can lead to significant cost savings.

Profitability Analysis

Calculating the production cost per unit allows businesses to assess their profitability more accurately. By comparing the average cost per unit with the selling price, businesses can determine their profit margin and make informed decisions about production volume, pricing, and market positioning.

Inventory Management

The production cost per unit formula is valuable for inventory management. It helps businesses determine the optimal production levels and avoid overstocking or understocking. By considering the average cost per unit, businesses can make strategic decisions about inventory levels, ensuring they maintain a balance between meeting demand and minimizing excess inventory costs.

Financial Planning and Forecasting

The formula is instrumental in financial planning and forecasting. It enables businesses to estimate their future production costs and revenue, aiding in financial projections and budget planning. This information is critical for securing financing, attracting investors, and making long-term strategic decisions.

Real-World Examples and Case Studies

Let’s explore a few real-world examples and case studies to illustrate the practical application of the production cost per unit formula:

Case Study: Automotive Manufacturing

Consider an automotive manufacturing company that produces high-end sports cars. The company aims to optimize its production costs to remain competitive in the market. By analyzing the production cost per unit, the company can identify areas for improvement. For instance, they might discover that labor costs are higher than industry benchmarks, prompting them to invest in automation and training to enhance productivity.

Case Study: Consumer Electronics

A consumer electronics company wants to expand its market share by offering affordable yet high-quality products. By calculating the production cost per unit, the company can set competitive prices while maintaining profitability. They can also use this information to negotiate better deals with suppliers and optimize their supply chain to reduce costs further.

Case Study: Apparel Manufacturing

In the apparel industry, where fashion trends change rapidly, understanding the production cost per unit is crucial for staying agile. A clothing manufacturer can use this formula to assess the profitability of different product lines and make informed decisions about which styles to focus on. By analyzing the cost structure, they can identify opportunities to streamline production processes and reduce overhead expenses.

Conclusion: The Significance of Production Cost Per Unit

The production cost per unit formula is a powerful tool for businesses across various industries. It provides a comprehensive understanding of the costs associated with manufacturing, enabling businesses to make strategic decisions, optimize operations, and maintain profitability. By regularly analyzing and monitoring this metric, companies can stay competitive, adapt to market changes, and drive long-term success.

FAQ

How often should businesses calculate the production cost per unit?

+

It is recommended to calculate the production cost per unit on a regular basis, such as quarterly or monthly. This allows businesses to track cost trends, identify any unexpected changes, and make timely adjustments to their operations.

Can the production cost per unit vary significantly between different products or industries?

+

Yes, the production cost per unit can vary significantly depending on the nature of the product and the industry. Factors such as the complexity of the manufacturing process, the cost of raw materials, and labor rates can all influence the average cost per unit.

How can businesses reduce their production costs per unit?

+

Businesses can reduce their production costs per unit by negotiating better deals with suppliers, improving efficiency through automation and process optimization, training and motivating their workforce, and regularly reviewing and managing overhead expenses.