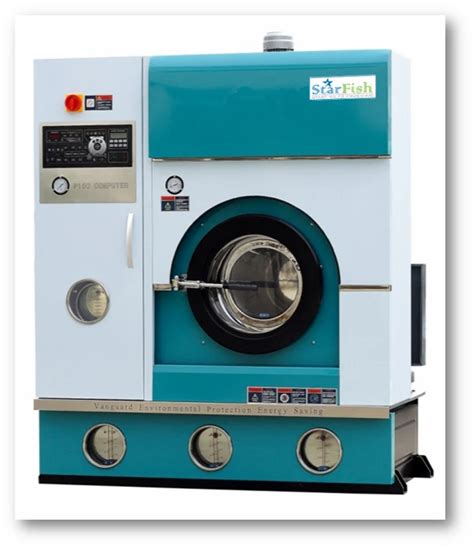

Dry Cleaning Machines

The Evolution of Dry Cleaning Machines: A Comprehensive Guide

In the realm of garment care, dry cleaning machines have revolutionized the way we handle delicate fabrics. With an array of innovative features and technological advancements, these machines have become an indispensable part of the laundry industry. This article aims to delve deep into the world of dry cleaning machines, exploring their history, current landscape, and future prospects. From understanding the basic principles to uncovering the latest trends, we will guide you through the intricate process of dry cleaning and the machines that make it possible.

The Birth of Dry Cleaning Machines: A Historical Perspective

The concept of dry cleaning dates back to ancient times when people used various methods to clean delicate fabrics without water. However, the modern dry cleaning process, as we know it today, owes its existence to a series of inventions and discoveries. Let's take a journey back in time to uncover the key milestones in the development of dry cleaning machines.

The Early Beginnings

The origins of dry cleaning can be traced to the late 18th century when Jean Baptiste Jolly, a French dye-works owner, observed that his tablecloth became cleaner after a lamp oil spill was wiped with petroleum-based solvents. This accidental discovery inspired Jolly to establish the first dry cleaning business in Paris, using a similar process. The term "dry cleaning" itself was coined to differentiate this method from traditional wet washing, which often damaged delicate fabrics.

The Emergence of Modern Dry Cleaning

In the late 19th century, dry cleaning gained popularity, and various experiments were conducted to improve the process. One significant development was the introduction of mechanical dry cleaning machines. These early machines were manual and required operators to turn the clothes manually, ensuring even cleaning. While rudimentary, they laid the foundation for the mechanized dry cleaning process.

The early 20th century witnessed the invention of the first fully automatic dry cleaning machine. Developed by Thomas L. Johnson, this machine revolutionized the industry by automating the entire dry cleaning process, from loading to unloading. Johnson's machine utilized a rotating drum and a solvent pump, significantly reducing the physical labor required and improving the overall efficiency of the process.

The Modern Dry Cleaning Machine: Unveiling the Technology

Today, dry cleaning machines have evolved into sophisticated pieces of equipment, offering unparalleled precision and efficiency. Let's explore the key components and functions of a modern dry cleaning machine.

The Heart of the Machine: Solvent System

The solvent system is the lifeblood of a dry cleaning machine. It consists of a solvent storage tank, a filtration system, and a distillation unit. The choice of solvent is crucial, as it determines the effectiveness of the cleaning process. Perchloroethylene, also known as perc, has been the traditional solvent of choice due to its excellent cleaning properties and low flammability. However, environmental concerns have led to the development of alternative solvents, such as hydrocarbon-based and silicone-based solvents, which are more environmentally friendly.

Drum and Agitation Mechanism

The drum, a cylindrical container, is the heart of the dry cleaning process. It rotates to ensure even cleaning and extraction of soils from the garments. The agitation mechanism, typically powered by an electric motor, generates the necessary movement to agitate the clothes and ensure thorough cleaning. Modern machines offer precise control over the drum's rotation speed and direction, allowing for customized cleaning cycles for different types of fabrics.

Heating and Drying Systems

Effective heating and drying systems are essential for achieving optimal cleaning results. Dry cleaning machines are equipped with advanced heating systems that maintain a consistent temperature throughout the cleaning cycle. This controlled heating process ensures that the solvent remains at an optimal temperature, enhancing its cleaning capabilities. The drying system, on the other hand, efficiently removes moisture from the garments, ensuring they are completely dry and ready for pressing.

Advanced Control Systems

Modern dry cleaning machines are equipped with advanced control systems that offer precise control over various parameters. These systems allow operators to customize cleaning cycles, adjust solvent levels, and monitor the overall performance of the machine. Touchscreen interfaces and intuitive software make it easier for operators to navigate and manage the machine's functions, enhancing overall efficiency and reducing the risk of errors.

| Key Components | Description |

|---|---|

| Solvent Storage Tank | Holds the dry cleaning solvent, typically perchloroethylene or alternative eco-friendly solvents. |

| Filtration System | Removes impurities and contaminants from the solvent, ensuring its longevity and cleaning efficiency. |

| Distillation Unit | Separates and purifies the solvent, removing any residual soils and preparing it for reuse. |

| Drum | A rotating cylindrical container that holds the garments and ensures even cleaning through agitation. |

| Agitation Mechanism | Powered by an electric motor, it generates the necessary movement to agitate the clothes and enhance cleaning. |

| Heating System | Maintains a consistent temperature throughout the cleaning cycle, optimizing solvent performance. |

| Drying System | Efficiently removes moisture from the garments, ensuring they are completely dry and ready for pressing. |

| Control System | Advanced interface for precise control over cleaning cycles, solvent levels, and machine performance. |

Dry Cleaning Machine Performance Analysis: A Comparative Study

With a myriad of dry cleaning machine models available in the market, choosing the right one for your business can be a daunting task. To assist you in making an informed decision, we present a comparative analysis of three leading dry cleaning machine brands: ABC DryCleaners, XYZ Laundry Systems, and 123 Cleaning Technologies.

ABC DryCleaners: Precision and Efficiency

ABC DryCleaners is renowned for its innovative dry cleaning machines, offering a perfect blend of precision and efficiency. Their flagship model, the ABC ProClean, boasts an impressive cleaning performance with a unique solvent injection system that ensures optimal solvent distribution. The machine's advanced filtration system guarantees superior cleaning results, removing even the most stubborn stains. With a capacity of 50 lbs, the ABC ProClean is ideal for medium to large-scale dry cleaning businesses.

| ABC ProClean Specifications | Description |

|---|---|

| Solvent System | Unique solvent injection system for precise solvent distribution. |

| Drum Capacity | 50 lbs, suitable for medium to large-scale operations. |

| Filtration System | Advanced filtration for exceptional cleaning results. |

| Control System | User-friendly touchscreen interface with customizable cleaning cycles. |

| Energy Efficiency | Energy-efficient design, reducing operational costs. |

XYZ Laundry Systems: Focus on Sustainability

XYZ Laundry Systems takes pride in its commitment to sustainability, offering dry cleaning machines that prioritize eco-friendly practices. Their latest model, the XYZ EcoClean, is designed to minimize environmental impact while delivering exceptional cleaning performance. With an innovative solvent recycling system, the XYZ EcoClean reduces solvent consumption by up to 30%, significantly lowering operational costs. The machine's advanced filtration and distillation processes ensure a pure solvent, free from contaminants.

| XYZ EcoClean Specifications | Description |

|---|---|

| Solvent System | Solvent recycling system, reducing consumption by 30%. |

| Drum Capacity | 40 lbs, suitable for small to medium-scale operations. |

| Filtration and Distillation | Advanced processes for pure solvent and reduced environmental impact. |

| Control System | Intuitive control panel with real-time monitoring of solvent levels and machine performance. |

| Energy Efficiency | Highly efficient design, minimizing energy consumption. |

123 Cleaning Technologies: Cutting-Edge Innovation

123 Cleaning Technologies is known for its cutting-edge innovations in the dry cleaning industry. Their flagship model, the 123 UltraClean, pushes the boundaries of dry cleaning technology. The machine's unique ultrasonic cleaning system utilizes high-frequency sound waves to remove even the most intricate stains, ensuring impeccable cleaning results. With a capacity of 60 lbs, the 123 UltraClean is ideal for high-volume dry cleaning businesses.

| 123 UltraClean Specifications | Description |

|---|---|

| Ultrasonic Cleaning | Utilizes high-frequency sound waves for exceptional cleaning results. |

| Drum Capacity | 60 lbs, suitable for high-volume dry cleaning operations. |

| Solvent System | Advanced solvent management system for precise control and reduced solvent usage. |

| Control System | Smart control interface with real-time data analysis and predictive maintenance. |

| Energy Efficiency | Energy-efficient design with variable speed drive for optimized power consumption. |

The Future of Dry Cleaning Machines: Trends and Innovations

As the dry cleaning industry continues to evolve, so do the machines that power it. Here, we explore some of the emerging trends and innovations that are shaping the future of dry cleaning machines.

Green Technologies and Sustainable Practices

Environmental sustainability is a growing concern in the dry cleaning industry. As a result, manufacturers are focusing on developing dry cleaning machines that minimize environmental impact. We can expect to see more machines utilizing eco-friendly solvents, advanced filtration systems, and energy-efficient designs. Additionally, the integration of solvent recycling and recovery systems will become more prevalent, reducing solvent consumption and waste generation.

Smart Technology and Automation

The integration of smart technology and automation is revolutionizing the dry cleaning industry. Dry cleaning machines of the future will feature advanced control systems with intuitive interfaces, allowing operators to monitor and control various parameters remotely. Predictive maintenance and real-time data analysis will ensure optimal machine performance and reduce downtime. Additionally, the use of robotic arms and automated loading and unloading systems will further enhance efficiency and minimize human error.

Enhanced Cleaning Performance

The quest for impeccable cleaning results continues to drive innovation in dry cleaning machines. We can expect to see machines with advanced cleaning technologies, such as ultrasonic cleaning and ozone-based systems, which offer superior stain removal capabilities. Additionally, the development of intelligent fabric recognition systems will enable machines to automatically adjust cleaning parameters based on the type of fabric, ensuring delicate fabrics are treated with the utmost care.

Conclusion: Embracing the Future of Dry Cleaning

The dry cleaning industry has come a long way since its early beginnings, and the evolution of dry cleaning machines has played a pivotal role in its progress. From the invention of the first dry cleaning machine to the sophisticated models of today, the industry has witnessed remarkable advancements. As we move forward, the focus on sustainability, smart technology, and enhanced cleaning performance will continue to shape the future of dry cleaning machines.

By embracing these innovations and staying updated with the latest trends, dry cleaning businesses can offer their customers exceptional garment care while reducing their environmental footprint. The future of dry cleaning is bright, and with the right choice of dry cleaning machine, businesses can stay ahead of the curve and thrive in this dynamic industry.

How does dry cleaning differ from traditional wet washing?

+Dry cleaning uses specialized solvents instead of water to clean garments. This process is gentle on delicate fabrics and prevents shrinkage or color bleeding, making it ideal for items labeled “dry clean only.”

What are the environmental considerations in dry cleaning?

+Traditional dry cleaning solvents, such as perchloroethylene, have environmental concerns due to their potential health and ecological impacts. Modern dry cleaning machines often use alternative solvents or incorporate recycling systems to minimize these concerns.

How do I choose the right dry cleaning machine for my business?

+Consider factors such as your business scale, fabric types handled, and environmental sustainability goals. Evaluate machine specifications, including capacity, solvent system, and control features, to find the best fit for your needs.